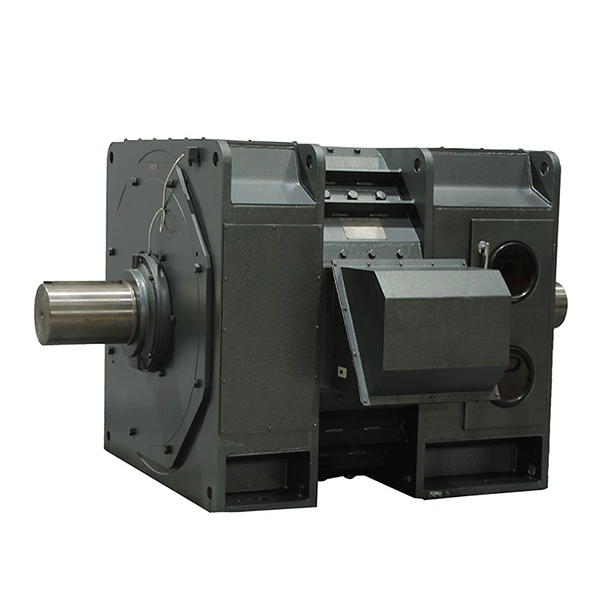

Z Series Medium Size Direct Current Motor

Z Series Medium Size Direct Current Motor Description

DC motor is a rotating motor that can convert DC electric energy into mechanical energy (DC motor) or mechanical energy into DC electric energy (DC generator). It is a motor that can convert DC and mechanical energy into one another. When it runs as a motor, it is a direct current motor, which converts electrical energy into mechanical energy; when it runs as a generator, it is a direct current generator, which converts mechanical energy into electrical energy.

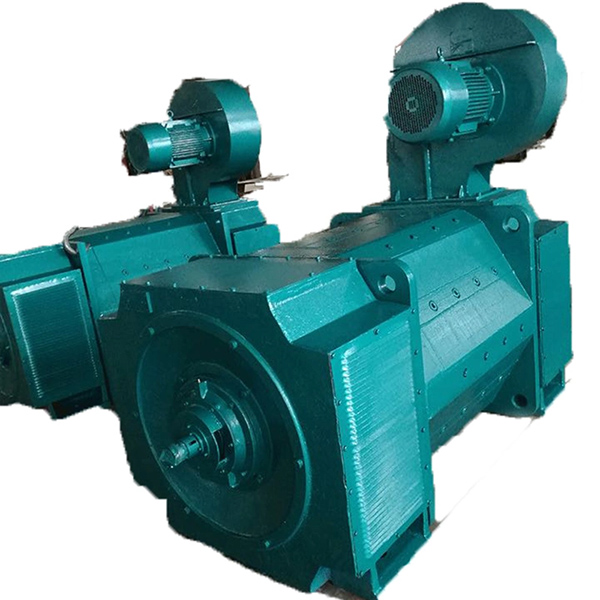

Z series Large Size DC motor used polygon structure so that the using rate of the stator’s inner space is very high. The magnet yoke is laminated style, suitable for silicon controlled commutate power supply and it can endure pulsating current and rapid change of current (load change).Magnetic poles are fixed by precise orientation. All the motors of system are with compensate winding, so the reverse performance is very well.

Z series medium size DC motors are newly products of the works developed with latest technology of design and manufacturing. There are six shaft heights for motor frames ranging from 315-560 mm.

The performance, outline dimensions and technical specifications of the motors conform to the standard of our country (GB) and International Electric Committee (IEC), while the mechanic dimensions tolerance of the motors conform to the standard of International Standard Organization (ISO).

Z Series Medium Size Direct Current Motor Features

The series brushed dc motors utilize polygonal configuration and stator with sufficient internal space being used. Stator with laminated magnetic yoke matched with SCR power supply is capable of withstanding loading under pulsing current or abrupt variation of current. Magnetic poles are precisely located and main motors of Z series having compensating windings can all provide a fine reversing function. Motor with insulation class F has reliable insulation structure and is dip-coated without solvent under vacuum pressure for ensuring stable insulation and fine heat emission.

Z Series Medium Size Direct Current Motor Performance:

1. Continuous working system (S1) is applied.

2. The standard rated voltage of this series motors are 220V, 380Vt 440Vt 550V and 660V. The voltage beyond above scope can be negotiated when placing orders.

3. Separate excitation is the basic excitation type of this series motors. Four terminals of the excitation winding are divided into two groups. In case the two groups are in series or parallel connection. the excitation voltage is 220V or 100V respectively. Excitation voltage beyond the scope can be negotiated.

Forced excitation is allowed with the voltage of less than 500V. During forced excitation I the transient excitation current can exceed the rated excitation current slightly until the excitation current gets stabilized.

4. Short time over-load capability:

Z Series Medium Size Direct Current Motor Description of Configuration

1.Cooling form and class of protection

a) Indirect cooling form available according to GB/T1993 “Cooling Method for Rotary Motor” has four standard types: IC06

IC07IC37 and IC86W. Their cooling air inlets are all located at the main drive end of motor (the non-reverser end). According to GB4942.1 hell Protection class (IP code) of Rotary Motor” protection classes of the series motors are IP23 and IP44. Other cooling form and protection class can be provided according to customer’s requirement.

2. Types and codes of motor configuration and installation

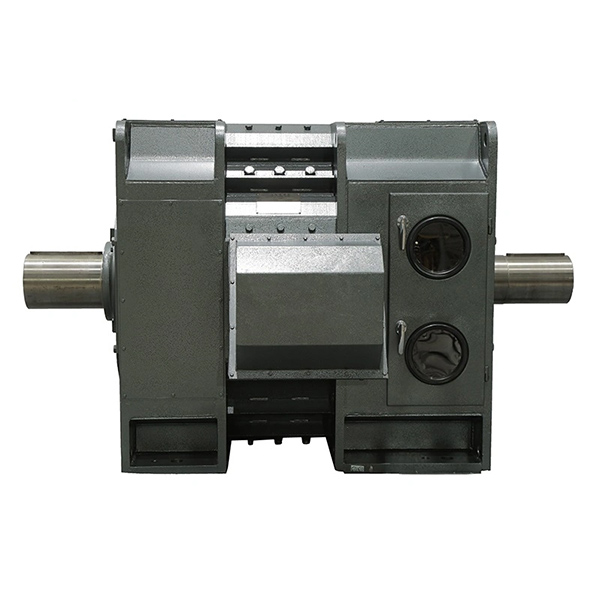

Types and codes of motor configuration and inst lation have two versions: IM1001 (horizontal typebody with base footings cylindrical single shaft) and IM1002 (horizontal typebody with base footingstwo cylindrical shafts) in conformance with GB.997 “Types of Configuration and Installation of Rotary Motor1M Code”. Other cooling form and protection class can be provided according to customer’s requirement.

3. For standard-type motorterminal box is located at the right side from main drive end. If it need be fixed on the left sidemake an indication when ordering.

4. Motor utilizes rolling bearing with oil filling during operation.

5. Motor can be fitted with the following accessories:

a) Temperature measuring elements are located in stator winding and bearing body and connected to terminal box of motor with lead.

b) Speed measuring and protective device including techogeneratorcentrifugal regulatorencoderetc is fitted at non driving end of motor.

c) 220V anti-condensation heater can be located in motor. If required, indicate it in ordering contract.

6. Air/water cooler is normally installed above motor. If user needs to position the cooler at the side place of motorit should be indicated when ordering and user must prepare its supporter.

7. Cooler is fitted with protective devices such as air pressure switchtemperature controlleranti-condensation heateretc.

Z Series Medium Size Direct Current Motor Technical Parameter

| Product Name | Medium Size Motor Electric DC Motor |

| Motor Type | DC Motor |

| Composition structure | The structure of DC motor should consist of two parts: stator and rotor. The static part of DC motor is called stator. The main function of stator is to generate magnetic field, which is composed of base, main magnetic pole, commutation pole, end cap, bearing and brush device. Running part is called rotor, whose main function is to generate electromagnetic torque and inductive electromotive force. It is the hub of energy conversion of DC motor. So it is also commonly called armature, which consists of rotor, armature core, armature winding, commutator and fan. |

| Model | Z Type |

| Seat number | Z315-Z1000 |

| power | 60~2800kW |

| Voltage | 220~1000V |

| Torque range | 1.5 ~180kNm |

| Protection level | IP23, IP44 |

| Cooling mode | IC06,IC17,IC37,IC81W |

| Operating speed | Constant Speed /Low Speed /Adjust Speed /High Speed Other |

| Main classification | DC Motor is a machine that converts mechanical energy into DC power. It is mainly used as DC motor for DC motor, electrolysis, electroplating, smelting, charging and excitation power supply of alternator. Although in places where DC power is needed, AC power rectifier is also used to convert AC into DC power, but from some aspects of performance, AC rectifier power supply can not completely replace DC generator. |

| Application | DC motors are widely used in tape recorders, video recorders, video discs, electric shavers, hair dryers, electronic watches, toys and so on. |

| Maintenance method | Professional motor maintenance center motor maintenance process: cleaning stator and rotor – replacing carbon brush or other parts – vacuum F pressure dipping paint – drying – Calibration balance. 1. Use environment should be always dry, motor surface should be kept clean, air intake should not be hindered by dust, fibers and other obstacles. 2. When the thermal protection of the motor continues to operate, it should be ascertained whether the fault comes from the motor or the overload or the setting value of the protective device is too low. After eliminating the fault, it can be put into operation. 3, ensure that the motor is well lubricated during operation. The general motor runs for about 5000 hours, that is to say, lubricating grease should be added or replaced. When bearing overheating or lubricating deterioration is found in operation, the hydraulic pressure should change lubricating grease in time. When replacing grease, the old grease should be removed, and the oil groove of bearing and bearing cover should be washed with gasoline. Then ZL-3 lithium grease should be filled with 1/2 (2 poles) and 2/3 (4 poles, 6 poles and 8 poles) of the cavity between the inner and outer rings of the bearing. 4. When the life of the bearing is over, the vibration and noise of the motor will increase obviously. When the radial clearance of the bearing reaches the following value, the bearing should be replaced. 5, when removing the motor, it is OK to remove the rotor from the shaft extension or the non extension end. If it is not necessary to unload the fan, it is more convenient to take out the rotor from the non-axle extension end. When pulling out the rotor from the stator, the stator winding or insulation should be prevented from being damaged. 6. When replacing the windings, the form, size, turns and gauges of the original windings must be recorded. When these data are lost, they should be obtained from the manufacturer and the original designed windings should be changed at will, which often deteriorates one or several performance of the motor or even makes it impossible to use them. |