We provide industry electric motor solutions

Success Project

WE PROVIDE HIGH QUALITY PRODUCT

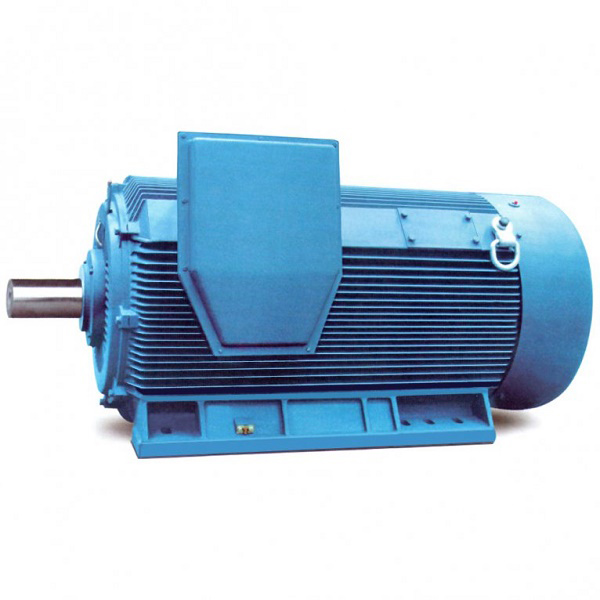

OUR PRODUCT

Trust us, choose us

About Us

Brief description:

Bulletproof Motor is an electric motor manufacturer and electric motor supplier. We supply single phase induction motor, three phase induction motor, squirrel cage induction motor, slip ring induction motor, wound rotor induction motor, explosion proof motor, ac motor, dc motor, variable speed electric motor, asynchronous motor, synchronous motor, high power motors (up to 10000 kW), high voltage motors (up to 13.8 kV), customized motors, gearbox, gear motor, speed reducers for decades in China. Thanks to the competitiveness both in quality, service and price, Bulletproof Motor's products are distributed to most of the countries and regions around the world, such as Bulgaria, Croatia, Romania, Slovenia, Turkey, Azerbaijan, Ukraine, Kazakhstan, Uzbekistan, Russia, Iran, Dubai, Yemen, Saudi Arabia, Egypt, Nigeria, South Africa, Sri Lanka, Chile, Peru, Bolivia, Argentina, Australia, Singapore, Malaysia, Vietnam, Thailand, Indonesia, Philippines and etc.